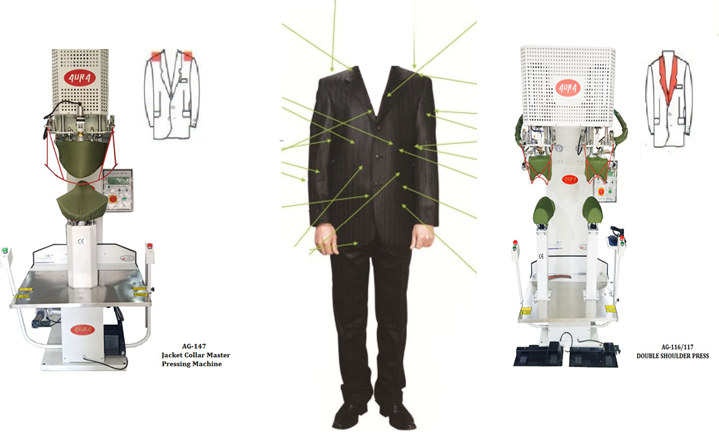

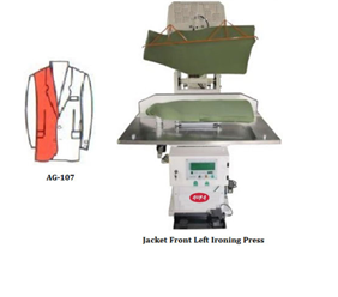

Jacket finishing machine

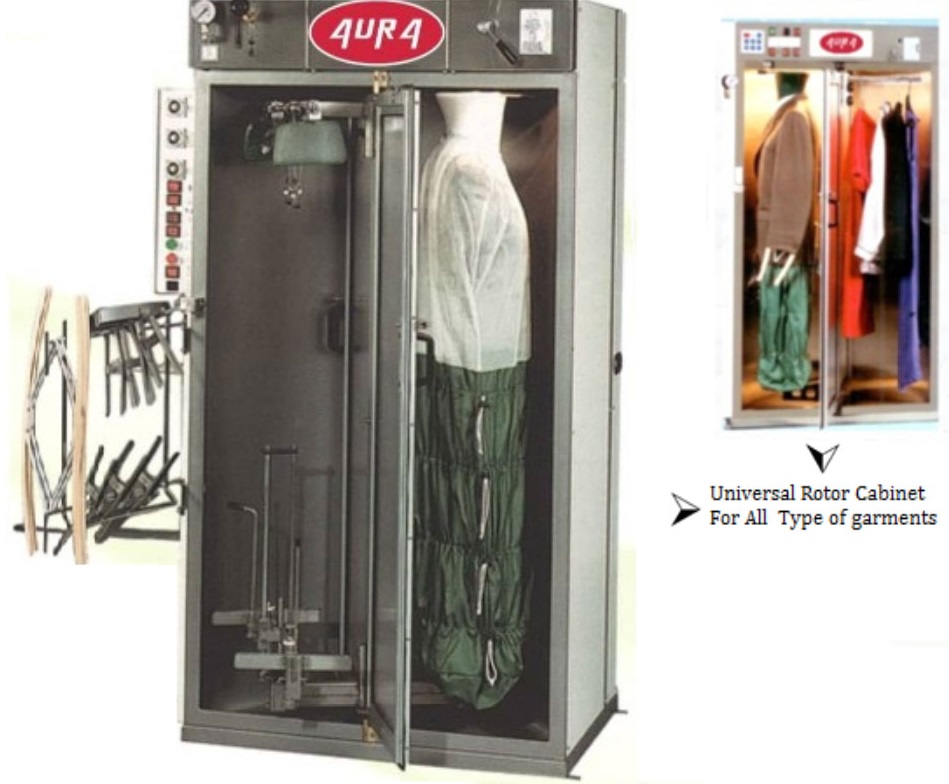

| Air Working pressure | 6-8 Bar | 6-8 bar |

| Steam working pressure | 4-5 bar | 4-5 bar |

| Steam consumption | 15-20 kg/hr. | 15-20kg/hr. |

| Overall size (in mm) | 415v 3 /td> |

| Required Power | 400v/3+N/50Hz |

| Water Feeding | Hosepipe 13mm |

| Steam Inlet | 1/2 |

| Return outlet | 1/2 |

| Steam working Pressure | 4-5 bar |

| Steam Consumption | 16-20 kg/h |

| Boiler Drain | 1/2 |

| Boiler heating | 10/12/15/18 kw |

| Pump Motor | 0.6 kw |

| Fan Motor | 0.75 kw |

| Warm air outlet | 160mm |

| Encumbrance |